The Blink DMI® process employs a unique combination of structural and digital technology to enable entire buildings to be manufactured and assembled from a kit of parts with tremendous speed and accuracy. Let’s examine the benefits of the patented Blink Backbone® structural technology and the applications it makes possible.

The Blink Backbone® has its origins in the more-than 35 years of engineering innovation and delivery of long-span, post-tensioned-steel structures by PT Blink Founder Murray Ellen. Through the fundamentals of physics and harnessing the laws of nature found in the works of Robert Hooke (1635) and Antoni Guadi (1852), Murray was able to achieve extremely long spans and open structures with both an efficiency of materials and an elegance of design. These same principles used in his stadiums, aircraft hangers and industrial and commercial facilities are found in the Blink Backbone® to achieve a lightweight building structure that enables freedom of design expression.

Like the chassis of a car, the Blink Backbone® is the datum for the whole building onto which all other components are fitted. It is the precise dimensional reference that enables the design and concurrent manufacture of all building components in a Blink DMI® property development project. This saves significant project time. Specifically, it enables property developers and owners to target overall time savings of at least 40%. It also achieves extremely accurate results, because components are designed and tested for fit prior to manufacture. There are many other benefits that we will discuss, including the following:

Architectural freedom: Enables a wide range of creative design expressions across multi-storey building typologies

Less CO2: The self-supporting post-tensioned steel structure allows less concrete and steel and a greener concrete to be used than conventional builds

High speed: At least 40% faster total project time than a conventional build, maximising the Internal Rate of Return for property owners and developers

Long spans: Creates open floorplans that can be reconfigured for different applications

Accessing air rights: Adaptive reuse maximises land value by building over existing assets such as car parks, heritage buildings and government facilities

Seismic stability: Courtesy of a low-weight, highly ductile structure

How does the Blink Backbone® work?

The Blink Backbone® comprises columns, trays and blade walls which are manufactured offsite and transported in a flat-pack form to the building site for integration. The structure fully integrates safety, reinforcement, building services and penetrations into the trays ensuring significantly faster and safer floor installation cycles. Once integrated, the columns and trays (and relevant blade walls) are filled with concrete. At this point, the structure behaves as a traditional composite steel and concrete structure, but without the need to correct for inaccuracies or for trades to then cut or drill it for penetrations.

Using post-tensioned steel cables, the Blink Backbone® enables large, self-supporting spans that are uninterrupted by columns. It also eliminates the need to rely on lift cores for lateral stability, as is typical of traditional construction methods. With PT Blink, the backbone components are simply craned into position, connected, checked for dimensional accuracy and poured, locking in the geometry with precision at that point.

By removing the need for a concrete core to be built and then measured before proceeding with the manufacture of other building components, the Blink Backbone® accelerates total project time. This is because the non-structural components can be manufactured concurrently with the structure itself as the dimensions are known and component fit is assured in the design-for-manufacture process. Akin to the just-in-time method of car manufacture, once the backbone structure (chassis) is erected, the other components are ready and waiting to be quickly integrated without delay.

No back-propping, formwork or scaffolding required

With a traditional concrete slab, propping is necessary to support the floor above for up to 28 days while the concrete cures to achieve full strength. The downside is that the presence of propping prevents work on the lower floor for that time. In multi-story developments, the multiplier of this time delay across the total project can be enormous.

With the Blink Backbone® there is no propping or formwork. Once the concrete is poured, the floor plate is accessible and ready for work from the next day, accelerating the property program. In addition, built-in safety edge protection means that there is no need for costly scaffolding.

Time is money - boosting the Internal Rate of Return (IRR)

In property development, time is literally money. The time delays of traditional construction methods mentioned above add significant cost to the project. Wasted time in construction also delays getting to market and realising the asset value for the property developer and/or owner. By slashing time potentially by as much as 40-60% across the entire program, PT Blink technology maximises the Internal Rate of Return delivering significant financial benefits to developers and owners. This also translates to a benefit for builders through increased annualised profitability due to being able to recycle capital resources faster and complete more jobs in the year.

Seismic performance

The Blink Backbone® technology offers outstanding earthquake response, allowing structures to deflect seismic forces significantly without failure. This is due to the post-tensioned steel offering greater ductility than conventional reinforced concrete structures. Also, weighing around half that of comparable traditional structures means that applied earthquake forces are similarly reduced. PT Blink’s post-tensioned steel technology is also well suited to foundation isolation systems and upper-storey damping mechanisms.

Lower-carbon structure

As above, post tensioning of steel increases capacity to carry load and span great distances, which enables thinner structures with less overall material. Thinner structures have the dual benefit of occupying less space per floor and less material. Less steel and the use of green steel can decrease embodied carbon of the structure. Additionally, the fact that the structure supports the weight of the curing concrete means that an even lower-carbon concrete can be used than with a traditional slab due to the longer time taken to reach full hardness.

Any architecture across building typologies

A key advantage of the Blink Backbone® is that the benefits of modularisation do not come at the expense of design. Specifically, the ability to tailor design to achieve the creative vision of the architect is not compromised. The Blink Backbone® can achieve any architecture and is suited to a range of multi-storey building typologies, including:

Retail / mixed use

Residential (build-to-sell or build-to-rent / multifamily)

Commercial

Industrial

Hotels

Medical facilities

Data Centres

It has even been used for a single-level pavilion-style building on a sloping block, mezzanine applications in existing buildings and is ideal for build overs to capitalise on airspace potential for infill developments.

The Blink Backbone® in action

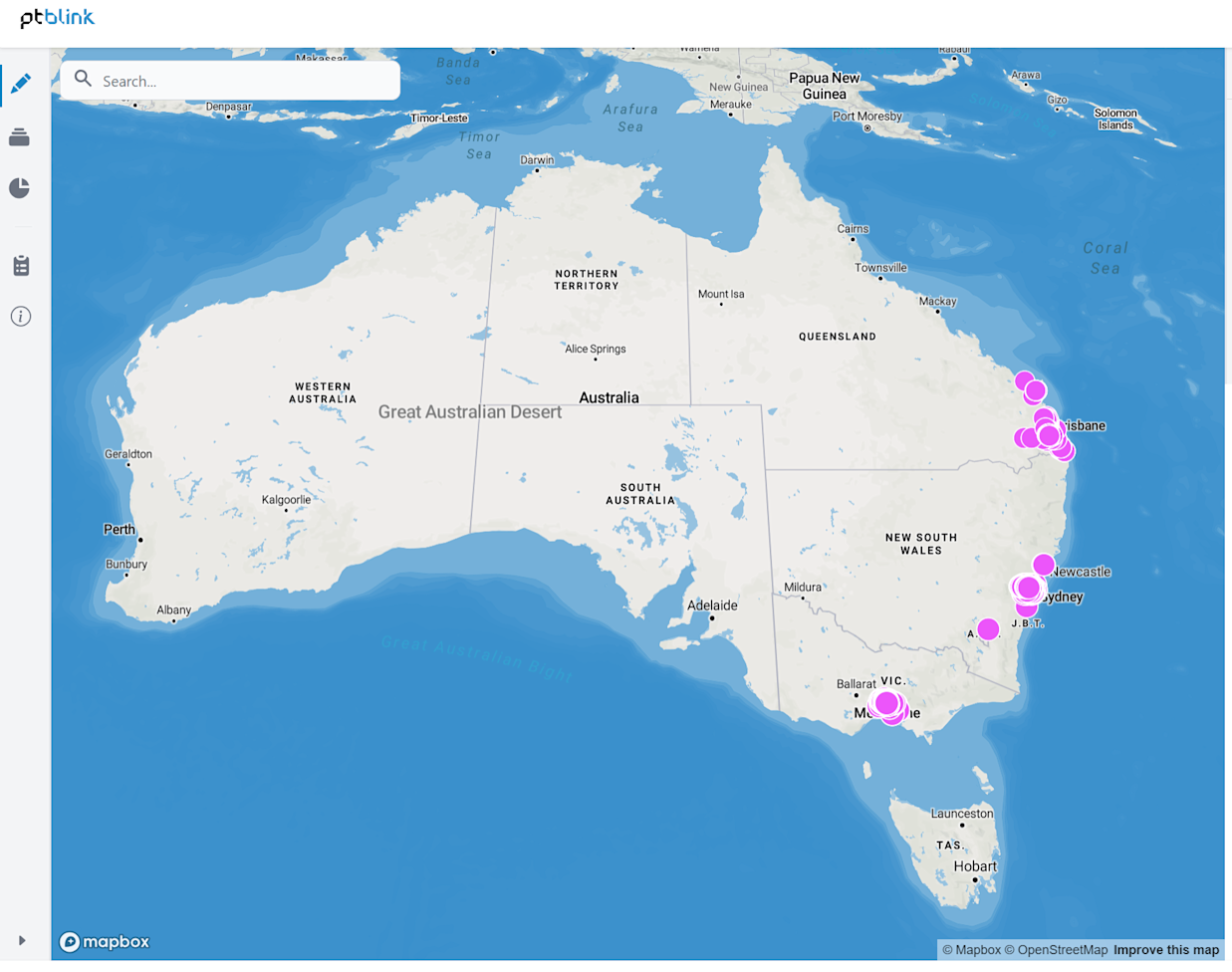

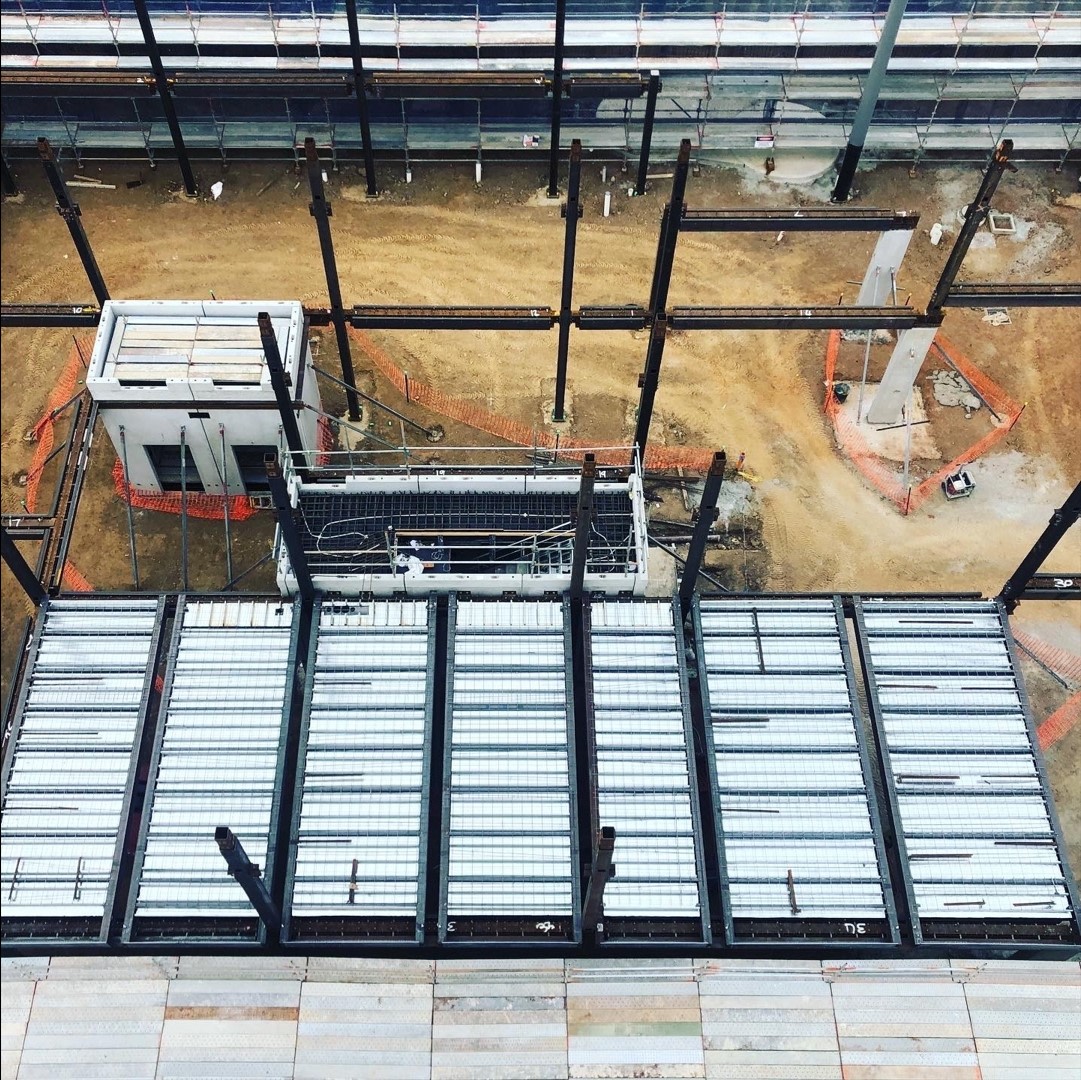

How do you lay 1000sqm of floor structure in a day? The answer is: using the Blink Backbone®. This multi-storey commercial development in Caboolture, Queensland used 43 post-tensioned steel trays per floor and enabled the structure to be erected one floor per day prior to pouring concrete.

The project achieved a 10kPa heavy-duty superstructure with a 9.75m clear-span grid. Trays arrived in flatpack form complete with penetrations and services installed. The post-tensioning eliminated the need for back propping which resulted in a very fast structure that allowed floorplate access the day after concrete pouring. Factory-based labour reduced the number of trades needed onsite making the site and surrounds less congested.

This multi-storey residential development in Spring Hill, Queensland achieved an astounding 7 floors of backbone structure above the podium in just 11 days. The resulting time saving saw the total project time reduced from 16 months to just 8 months, rapidly accelerating the time to market and changing the financial feasibility for the whole development.

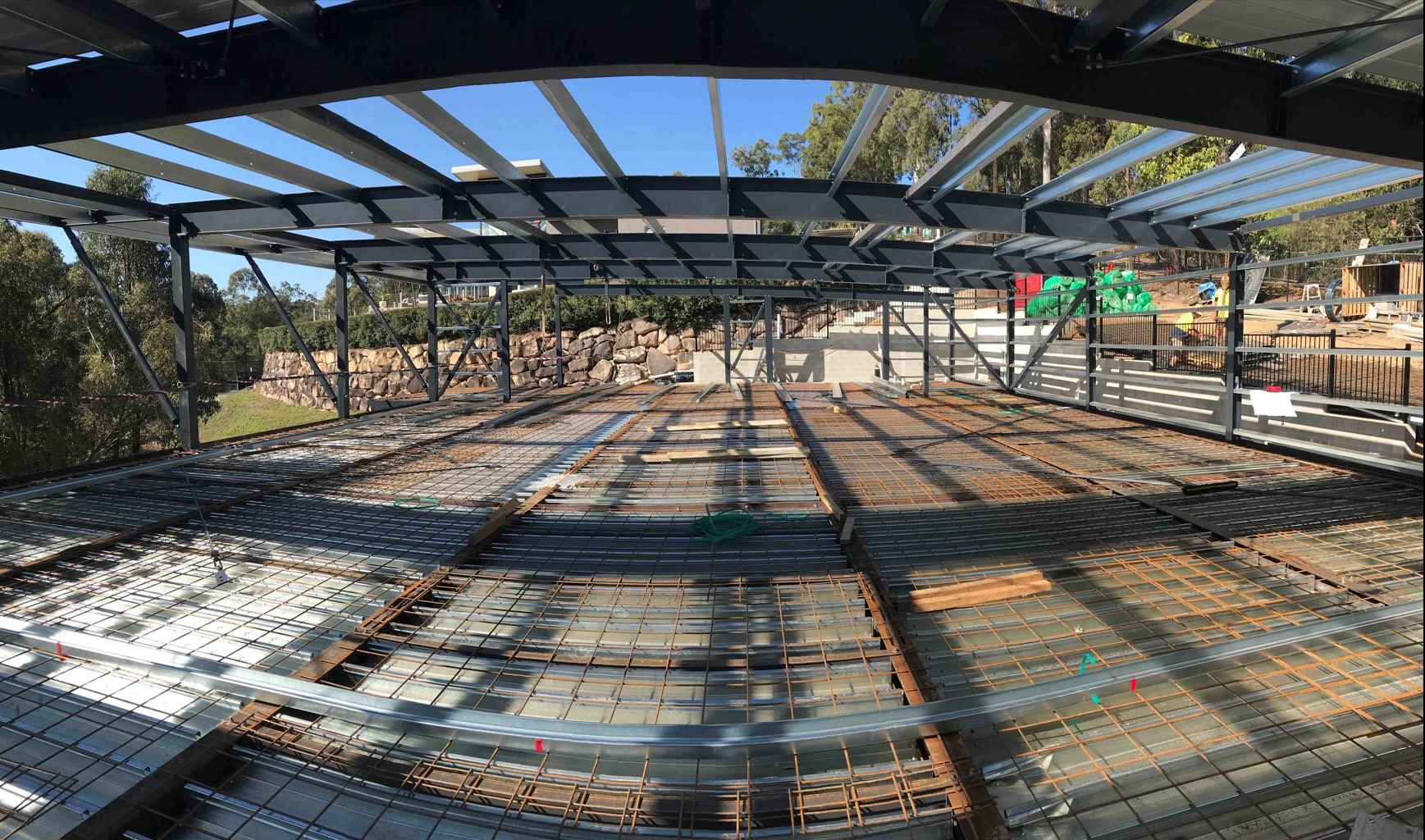

This luxury car showroom used the Blink Backbone® to great effect, achieving a stunning space overhanging the hill to capitalise on the view. Features included:

Large clear span with no columns to interrupt the space created for 10 cars

The ability to produce floor trays for any shape, in this case graceful curves to enter the showroom

The ability to overcome a sloping block quickly and efficiently with very fast installation

Combining stressed trays and non-stressed infill trays minimised steel, and reduced manufacturing costs by 30%-40% where deeper support beams are possible

This technology applies to multi-storey office, commercial, industrial and residential buildings as well as schools or single dwellings such as pavilion-style houses looking to make the most of a view. It can also be easily scaled for rapid construction of heavily loaded multi storey warehousing and distribution centres.

Once poured, the Blink Backbone® behaves as a composite slab. Of course, all the hard work is done before the structure even reaches the site. Reinforcement is installed in the factory. So too are the set downs, hob formers and screed rails. Just add concrete!

There's no need for drilling what will be a pristine polished concrete floor. And no back-propping means the underside is immediately accessible. Simple, efficient and very fast!

Airspace developments

Airspace developments present a huge opportunity to deliver necessary property assets where they are needed most. This maximises land usage and adds value to existing properties. Adaptive reuse is also the most sustainable form of infill development requiring no new land releases.

The Blink Backbone® structural technology offers a wide range of options to build over existing assets, taking the structural load to the ground either within the existing building or outside. Likewise, facades can be integrated to preserve the original building in the case of heritage buildings or that create a new expression altogether. With the Blink Backbone® the sky is not the limit!

Do you have a development project? Book a FREE initial consultation today to see how Blink DMI® can work for you.

__________________________________

About PT Blink

PT Blink enables the Blink DMI® process of creating multi-storey structures faster, safer, better and with less waste than traditional construction. With the unique Blink DMI® process, owners and developers deliver multi-storey buildings as a kit of configurable parts that are manufactured offsite and integrated very quickly and safely onsite by ecosystem partners.

Blink DMI® minimises property project risks for owners and developers by bringing visibility, control, assurance and modern manufacturing precision to any property asset.

For Blink DMI® partners, the method provides access to an ecosystem of projects and opportunities to deploy existing capital infrastructure.

About Murray Ellen

PT Blink Founder Murray Ellen is a global expert in post-tensioned steel technology and has conceived, designed and implemented projects in countries including Australia, China, United Kingdom, Hong Kong, Malaysia, Philippines, Thailand, Taiwan and Dubai.

Murray’s broad experience includes full technical implementation, construction and development responsibility for projects which he has delivered with excellence around the world. His innovative steel design technology and construction methodologies for large-spanned structures have received multiple awards and are unique in the global steel spectrum.

Today Murray empowers and inspires a team to build on his more-than 35-year legacy, IP portfolio and original vision to deliver the built environment FASTER, SAFER, BETTER and with LESS WASTE through technology.

Murray also currently serves as a Governor of Sydney University’s Warren Centre for Advanced Engineering and is a Fellow of the Australian Academy of Technological Sciences and Engineering.

________________________________________

Related article: Save around 40% of construction project time