Trafalgar Group is a proudly Australian-owned and operated business that has been creating specialty building products and solutions since 1945. With a heritage in commercial bathroom products, first aid kits, safety cabinets and other safety equipment, the business was purchased in 2009 by John Rakic. Under John’s leadership, Trafalgar has diversified and grown with the spirit of innovation and commitment to developing unique fire-safety solutions for the built environment at the fore.

Trafalgar has a proud history dating back to 1945. What attracted you to buy it back in 2009?

I was lucky enough in the mid 1990’s to work on a product development project for a fire-rated access panel product with the founder of Trafalgar. In my time at Tyco International we acquired Trafalgar. First aid was sold off and I was involved in relocating the sheet metal manufacturing operations of Trafalgar and integrating them into a much bigger sheet metal manufacturing operation for Tyco.

In 2009, I was approached by the Norfolk Group, who had subsequently purchased Trafalgar, to buy the assets of the former Trafalgar, including the name and heritage. I thought it was nice to see Trafalgar back as a family owned and operated Australian company after some time under public listed ownership.

What are Trafalgar’s primary product groups today?

We service the construction, safety and transport industries through five specialised Trafalgar Group companies all manufacturing locally here in Australia:

Trafalgar Access: Offers the full range of access panels for walls, ceilings and service shafts, specialising in acoustic-rated and fire-rated, metal and wood/MDF panels that meet demanding performance and aesthetic standards.

Trafalgar Fire: More than 400 certified passive fire products and systems. These include: fire-rated sealants and mastics, fire pillows, fire collars, fire rated boards, fire-rated access panels and fire-rated mortar.

Trafalgar Safety: Safety storage products including cabinets for dangerous goods, chemicals and tools; stillages and pallets; site boxes and ute boxes.

Trafalgar Innovation: A team with strong industry relationships and dedicated to anticipating and responding to the rapid changes and opportunities in the construction market. This is where ideas are researched, generated and tested to offer customers new solutions.

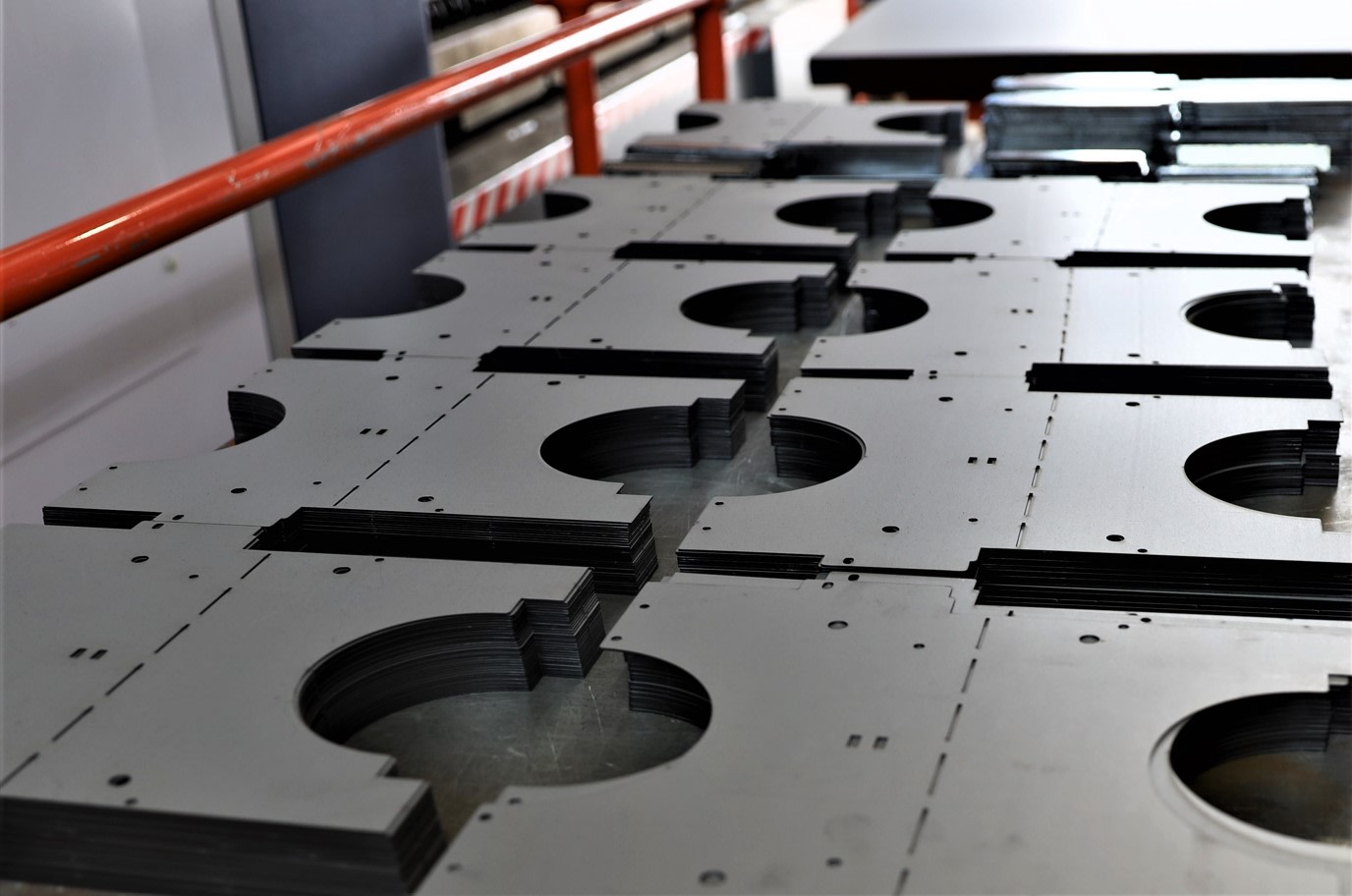

Trafalgar Manufacturing: Our inhouse manufacturing team responds to customer briefs and also takes the concepts developed by our innovation team to conduct rapid prototyping and concept testing. This is a one-stop-shop – from 3D modelling through to production, assembly, packing and dispatch.

How do you describe the Trafalgar difference?

I think it’s summed up in our Values statement. Each of the five points means something to us and affects how we operate day-to-day.

The pride we feel to be locally owned and operated combines with the value we place on our people, partnerships and local community. In a global world that is a critical difference. We spend time with our customers, suppliers and stakeholders. We get to know their needs, design customised solutions, try and test new ideas and follow them through into the field. That local commitment to quality, safety, sustainability and long-term relationships is what makes us a trusted partner year in year out for decades. Our focus on innovation is what keeps us at the forefront of customers’ minds and keeps us always relevant because the world is continually changing.

What is your vision for Trafalgar Group?

Trafalgar operates under important principals which are important to all employees:

Family first – We think a kid’s graduation or soccer final is important so insist that employees do these things and provide the flexibility for this to happen.

FUN – We think it is important to respect all employees, treat them all as equal and make them feel as though they are making a difference.

Work Smarter Not Harder – We live by continuous, small-step improvements and invest heavily in our people, process and new and innovative machinery to improve productivity.

Continuous Improvement is better than delayed perfection (Mark Twain) – We encourage quick decisions with no penalty for failure. We need to move fast and be innovative so we can maintain market leadership positions in our chosen markets.

As a building products manufacturer, what challenges are you seeing in the construction industry today?

We have worked through COVID and during these tougher times we invested hard in people and systems, allowing staff to work from home and stay involved and productive. In terms of building products, the overseas supply chain disruptions saw construction need to revisit Australian-made products and we were well positioned to support the local construction market. Material shortages, new changes to Building Control Legislation, stricter enforcement particularly in passive fire protection has seen us need to develop, fire test and bring systems to the market which save labour and cater for offsite construction or modern methods of construction.

How does the Blink DMI® process help you as a manufacturer?

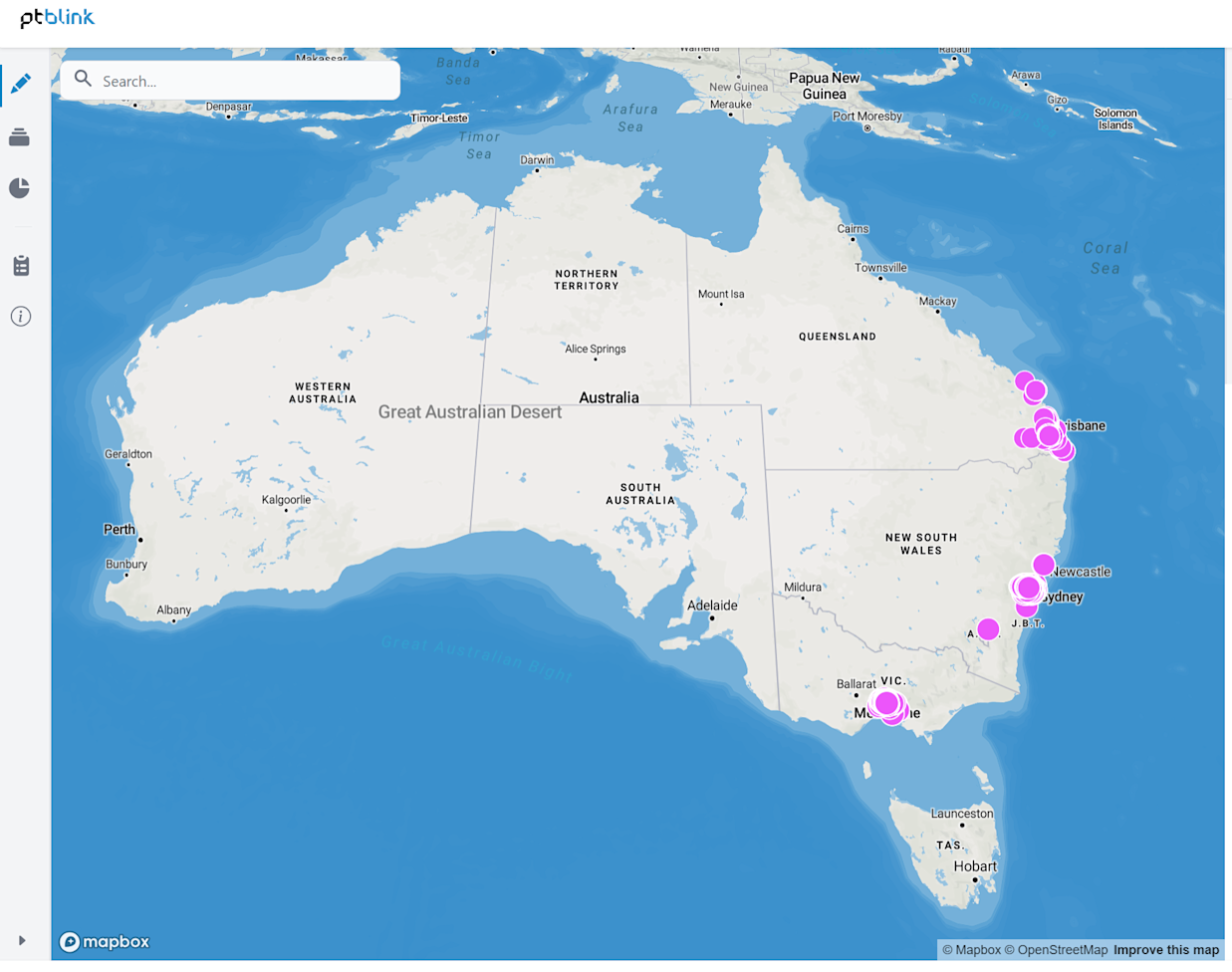

PT Blink is perfect for Trafalgar as our robust and fully complaint passive fire protection systems augment what PT Blink is about.

We have some structural fire proofing board systems which cater for the PT Blink structural platform coupled with cast in fire stop systems which can be incorporated into the structural trays to save time, money and make compliance guaranteed.

What are your aspirations for manufacturing in Australia?

I was told by highly paid consultants that I was mad investing in local manufacturing for the 10 years before COVID; I was told that my love and passion for manufacture was nothing more than a glorified hobby. Despite these recommendations my team and I continued our productivity improvements to compete with “China”.

Fast forward to today, and I am so glad I did not offshore like the rest of Australia.

We are a good local manufacturer and we enjoy what we do. For me, we will continue to grow our manufacturing base and keep providing employment opportunities for people in Western Sydney.

________________________

Are you a designer, manufacturer or integrator (builder)? Register your interest in becoming a Blink DMI® Partner today.

Related article:

- Manufacturers: Top 5 reasons to become a Blink DMI® partner