Accredited integrators ensure a cohesive process

As Blink DMI® ecosystem members, integrators engage the manufacturing partners to ensure compliance, sequencing and end-to-end cohesion in the integration process.

Integrators are licensed to participate on the Blink DMI® platform having undergone the same accreditation process as the other ecosystem members.

As a result of the design process and the digital twin as the single source of project truth, components can be individually tracked, catalogued and verified at every stage of transport, storage, delivery and onsite integration.

High-level BIM coordination

High-level BIM coordination between MEP services, façades, internal partitions, stairs, lifts and other elements enables onsite installation to be verified by the ‘digital twin’.

This provides integrators with the ability to view the coordinated 3D modelling at 1:1 scale in real-time while onsite.

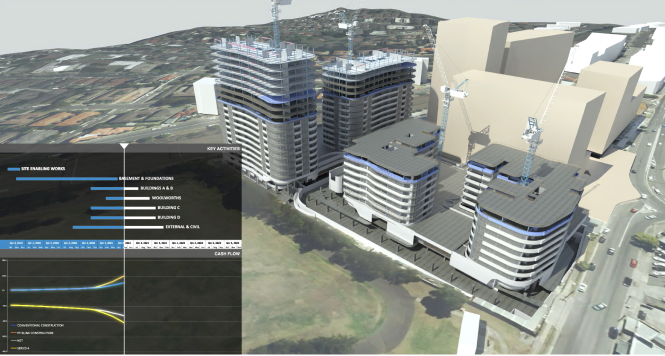

4D simulations and pre-emptive risk detection

Installation timeframes are dramatically decreased due to 4D simulations. These accurately model the project spend and installation programme with the 3D model.

Integrators are able to see the installation down to the nut and bolt level in the software prior to any manufacturing. This allows for pre-emptive qualitative and onsite risk assessments.

An open and transparent communication platform between manufacturer, designer and integrator ensures collaboration.