In February 2023, I had the pleasure of addressing the Stanford University Industrialized Construction Forum, an annual showcase of global technology innovation to deliver the built environment. I was invited to speak on the theme of Distributed Networks of Manufacturing. The audience was large – around 250 – and varied: VCs, manufacturers, academics, architects, engineers, and construction, infrastructure and technology companies. My fellow speakers were also varied. Yet, despite any differences among all of us in the room, one thing was clear – we were united from the outset to make change now for a better world.

Perhaps due to our time in history, the mood was charged with an energy that said, “the time for talk is over”. 2023 had just started, picking up where 2022 had left off, and it wasn’t looking pretty. Like a deer in the headlights in the middle of the freeway, the construction industry was frozen. Media commentary continued serving up the casualty stats and the prognosis of more to come. Rising interest rates to combat 40-year-high inflation, acute labour shortages, supply chain disruption, rain and extreme weather delays, all coming to bear at once.

Construction companies were falling like dominoes in 2022 and early 2023 showed no signs of this changing. The following months would show a year-on-year acceleration of construction insolvencies, with more than 2,500 collapses in Australia since 2021. Behind each major company failure there are employees and customers immediately affected by stress, uncertainty and financial loss. Less visible though are the hundreds of faceless subcontractors – mostly small family businesses – bearing the brunt of risk pushed downstream and not being paid.

At the same time, on the demand side, we have huge unmet requirements for social and affordable housing for thousands on waiting lists more than a decade long. In Australia, there is an estimated shortfall of at least 500,000 social and affordable houses nationwide. As interest rates rises continue to bite, a cost-of-living crisis is now hitting our communities indiscriminately, with families living in cars, tents or couch surfing wherever they can. The not so fortunate live rough on the streets. The situation is dire and unacceptable in any time but in 2023 there is no excuse.

So, let’s return to the deer in the headlights. We can choose not to learn from the past and look only at the status quo way of doing things or we can look for a BETTER way. The former means we make no fundamental changes to the process and continue to focus on variables out of our control such as costs, labour shortages and weather events. We can keep shuffling them around, forecasting and allowing for delays and optimising process elements with point solutions in the vain hope that we will make any improvement at all. But the improvement needed is immense and, like compound interest, grows larger by the day. Blinded from considerations of other possibilities, this status-quo approach is akin to the pursuit of a faster horse rather than looking at the root problem and devising a new form of transportation.

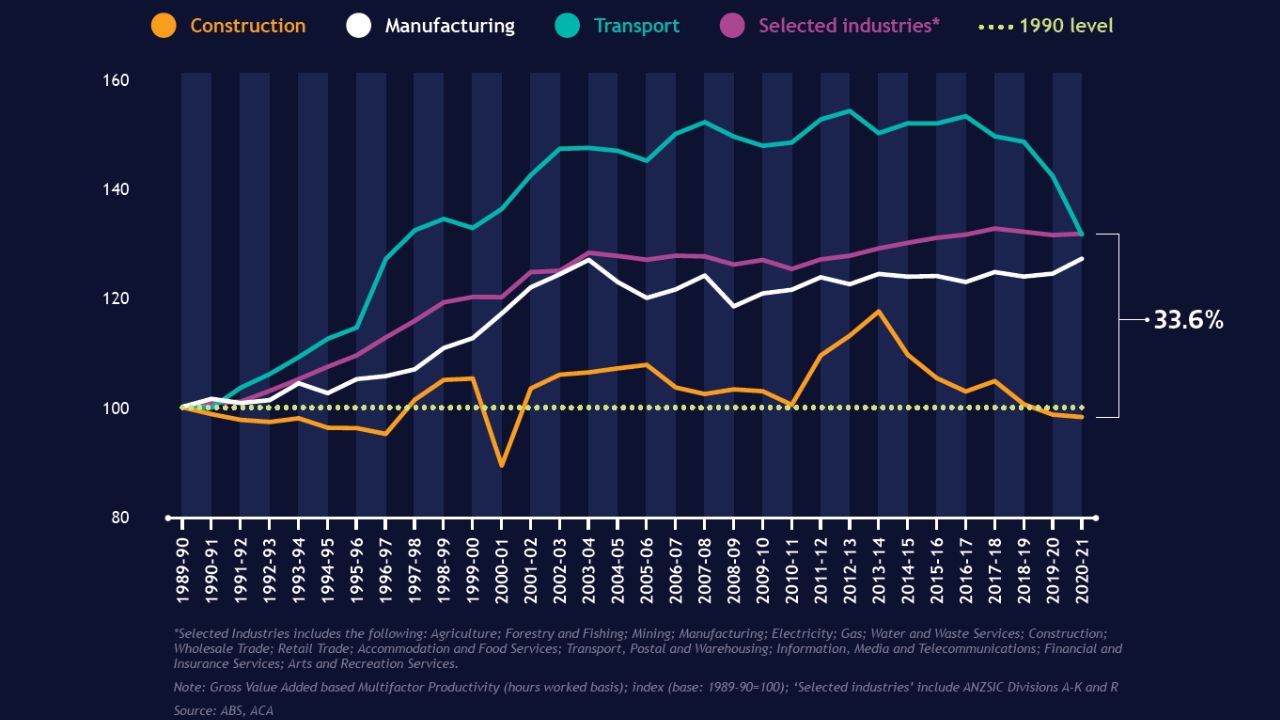

The poor productivity performance of Australia’s fourth largest industry is costing the economy $47 billion annually and is indicative of a business that is stuck in the past. (Australian Constructors Association)

In November 2022, the Australian Constructors Association released their report Distrupt or die: Transforming Australia’s construction industry. Featuring data from BIS Oxford Economics and McKinsey, the report pulls no punches on the state of the industry. Among the data it revealed that construction industry productivity has declined a massive 16.5% since the peak of the resources boom in 2014 and overall was 1.8% lower in FY2021 than it was in FY1990. This is an average growth rate of -0.1% per annum since FY1990.

Clearly, we have a productivity problem, but we also have social and economic issues to solve: more construction businesses fail than any other industry; margins are wafer thin; workers are six times more likely to die from suicide; diversity is low; women make up just 12% of the workforce; and less than one third of Gen Z would consider a career in construction. From an ecological standpoint, waste is too high and the built environment contributes 38% of global carbon emissions.

To quote the report: “Government, industry and unions all agree on the opportunity and, more importantly, the need for change. Incremental change and 10-year horizons are out. To keep the industry alive, it must transform.” So, the only question to ask is, what are we waiting for?

There is a better way!

The answer to the problem we all face is a fundamental change in the way the built environment is delivered and operated. Rather than continuing low-tech, labour-intensive building approaches, we must embrace the innovation shown and celebrated at Stanford University – we must Design, Manufacture, and Integrate buildings locally, and collaboratively. This is our focus at PT Blink, and we call the methodology Blink DMI®.

By leveraging the power of distributed networks of manufacturing we can tap into existing capital infrastructure, to scale around projects and invest in local communities, jobs creation and economic prosperity. The same principle applies for all other members who form an ecosystem of opportunity to add and receive value – from designers through to building integrators. They are all brought together to collaborate early at the design phase and remain together through manufacture and integration.

It's time for a new process that values time and minimises waste.

Quality, productivity and operational efficiency are maximised though a combination of parametric design, concurrent offsite manufacture of the structure and other components, and onsite integration using just-in-time principles. Key benefits include:

Target at least 40% total project time savings. By halving total project times, twice as many jobs can be completed with the same capital resources. This changes the financial equation from a focus on cost – which is also reduced – to a focus on early realisation of asset value and capital redeployment. I have written previously that time is the most underrated commodity in construction.

Minimising material waste maximises financial return while substantially benefitting the environment. Minimising the waste of time on design iterations through parametric design algorithms and the need for rework due to accurate design-to-manufacture processes cut costs and accelerate speed to market.

Offsite manufacture in safe and controlled environments eliminates the impact of weather events as the structure and building components are made. Concurrent manufacture of structure and non-structural components slashes time.

Onsite integration using the unique Blink Backbone® (the chassis of the building) eliminates the need for a concrete building core, taking the structure off the critical path and accelerating the entire project delivery. Importantly, floor plates can be completed in days not weeks, which enables a weatherproof envelope to be created very quickly so the building fit out can be completed with speed and certainty.

Design for performance attributes such as embodied carbon down to a component level enables unprecedented understanding and control of built assets’ environmental impacts.

Digital twin and sensor technology optimise performance in the operational phase.

Let’s raise the tide together for the benefit of all.

The technology, ecosystem, opportunity all exist today. The need for change is at crisis point. By embracing a new way and working together, we can solve the productivity crisis, build value back into the industry and deliver the growing housing and infrastructure capacity that is required. The time to act is now so let’s raise the tide of the industry and lift everyone’s boat.

Do you have a development project? Book a FREE initial consultation today to see how Blink DMI® can work for you.

About Murray Ellen

PT Blink Founder Murray Ellen is a global expert in post-tensioned steel technology and has conceived, designed and implemented projects in countries including Australia, China, United Kingdom, Hong Kong, Malaysia, Philippines, Thailand, Taiwan and Dubai.

Murray’s broad experience includes full technical implementation, construction and development responsibility for projects which he has delivered with excellence around the world. His innovative steel design technology and construction methodologies for large-spanned structures have received multiple awards and are unique in the global steel spectrum.

Today Murray empowers and inspires a team to build on his more-than 35-year legacy, IP portfolio and original vision to deliver the built environment FASTER, SAFER, BETTER and with LESS WASTE through technology.

Murray also currently serves as a Governor of Sydney University’s Warren Centre for Advanced Engineering and is a Fellow of the Australian Academy of Technological Sciences and Engineering.

About PT Blink

PT Blink enables the Blink DMI® process of creating multi-storey structures faster, safer, better and with less waste than traditional construction. With the unique Blink DMI® process, owners and developers deliver multi-storey buildings as a kit of configurable parts that are manufactured offsite and integrated very quickly and safely onsite by ecosystem partners.

Blink DMI® minimises property project risks for owners and developers by bringing visibility, control, assurance and modern manufacturing precision to any property asset.

For Blink DMI® partners, the method provides access to an ecosystem of projects and opportunities to deploy existing capital infrastructure.