Based in Smithfield in Sydney’s Western Suburbs, Kavanagh Industries (KI) is a progressive local manufacturer and the largest specialised supplier of sheet-metal ducting for heating, ventilation and air conditioning (HVAC) in Australia. A family-owned business, KI is operated under the guidance of Managing Director, Aidan Kavanagh, who has steered the evolution of the company for the past 30 years. We spoke to Aidan about the reality of manufacturing in Australia, the challenges facing his business today and the opportunities for new approaches to construction.

How has KI evolved as a business?

30 years ago, we were one company, Kavanagh Ventilation, with five people. Today we are eight companies with more than 300 employees, and revenues of over $100 million spanning HVAC, screw piers, solar carpark structures and everything in between.

Back in the day we were basically a commodity-based business supplying ductwork. A piece of duct is just a product. But if we can supply and install ductwork then we’re supplying a service. Take that further, if we can do prefabrication and offsite pre-assembly then we’re selling bigger pieces of product that other people struggle to match. And then we go into multi-trade where we incorporate pipework and ductwork in a frame and offer customers a complete value-add solution based on a problem: the need to have complex services installed in a short time frame.

So, it’s about adding value?

Yes, rather than the client stick-building onsite, we can drop multi-service modules in. Taking it further, we can do the supply, install, plumbing and prefabrication. It takes a huge headache away from the customer and for us a $2M or $3M duct-supply contract becomes a $17M contract because we’re selling a full turnkey solution rather than a commodity.

What benefits do you see as a Blink DMI® Partner?

The Blink DMI® process is ideal for us because it maximises our ability to complete work in the factory and integrate the full solution onsite using the just-in-time principles of lean manufacturing. Blink DMI® enables design for any architecture so design flexibility is a huge benefit for the end user. Within that, we see opportunity for component level standardisation and modularisation as a huge benefit of the platform and catalogue approach. For example, as manufacturers we can offer modules at an optimal size to suit the truck sizes for efficient and cost-effective logistics. Instead of one big riser with an exoskeleton you might build two smaller units that dramatically reduce transport costs. That's what the term DfMA (Design for Manufacture and Assembly) is all about – buildability. It means you don’t go bigger than a wide load unless you have to. You don’t make things that can’t be picked up and turned over in your factory. You build within your crane capacity. Everybody wins because it builds in predictability and efficiency upfront.

How does the Design – Manufacture – Integrate process change things for you?

Concurrent manufacture of structure and componentry is a game changer. You can basically put a placeholder in the design very early in the process for say a complete plant room. We can then design in parallel with the structure (Blink Backbone®) design and coordinate it in the 3D world.

Then we build and prefabricate the plant room offsite simultaneously with the structure. Instead of sequential production onsite, where things cannot progress without the previous step being completed, we’re building our part before the building is ready. Again, everybody wins because you have certainty of the quality, delivery and cost. As a business, we can manage our capacity better and take on more work in the knowledge that we can deliver on our promise.

Are you seeing a shift to this approach?

Clients who understand the value of time and the time value of money get it where others don’t. Data centre operators get it because they sell time. Big centres lease out at $1M a week, so if you can pull the project in a couple of months early, that’s big dollars.

What are the biggest challenges in construction now?

The jobs aren't running fast enough. We've had so many delays with Covid supply chain challenges – problems with getting raw materials and cost blowouts on the materials. Now we've got problems with tradespeople and problems with rain. Rain on a construction site is a killer. The factory can continue making if we're building the building offsite, but we can't make it on a construction site. We get rained off.

So, anything we can do offsite in parallel to that construction site is a big win for us and then it comes down to our yard capacity and space capacity. Ultimately though, the linear onsite process of traditional construction holds you up which compresses the schedule and limits us from taking on new jobs.

Blink DMI® helps you with capacity?

Absolutely. If it rains like it has this year, the finish date will still not change on that job, so all we're going to do is get compressed towards the end of the job. If we were not working onsite, we could still be manufacturing in the offsite environment and then put in the small amount of labour component onsite at just the right time to integrate into the building. The rain doesn’t really affect us that much for the integration stage.

What sort of labour savings are you seeing with prefab?

There is a circa $2B hospital job coming up in Adelaide and, if you look at the mechanical component of that, you'll end up with about 360 to 400 workers on site at peak. For the builder, consider how many lunchrooms they need? How many toilet facilities and safety components? The wages for manpower on that site? We can reduce that by 60 to 70% using offsite manufacture. That’s just mechanical, so imagine the potential reductions in people, facilities and safety risks onsite of a full Blink DMI® build in addition to the time saved.

Localised labour shortages are another consideration.

That’s right. There's not enough skilled labour in South Australia to do a job like that. I like to say that stress causes innovation. There are not 380 skilled mechanical tradespeople in Adelaide, so we have to innovate, and we'll probably prefabricate the job by drawing on resources from across Adelaide, Sydney and Melbourne.

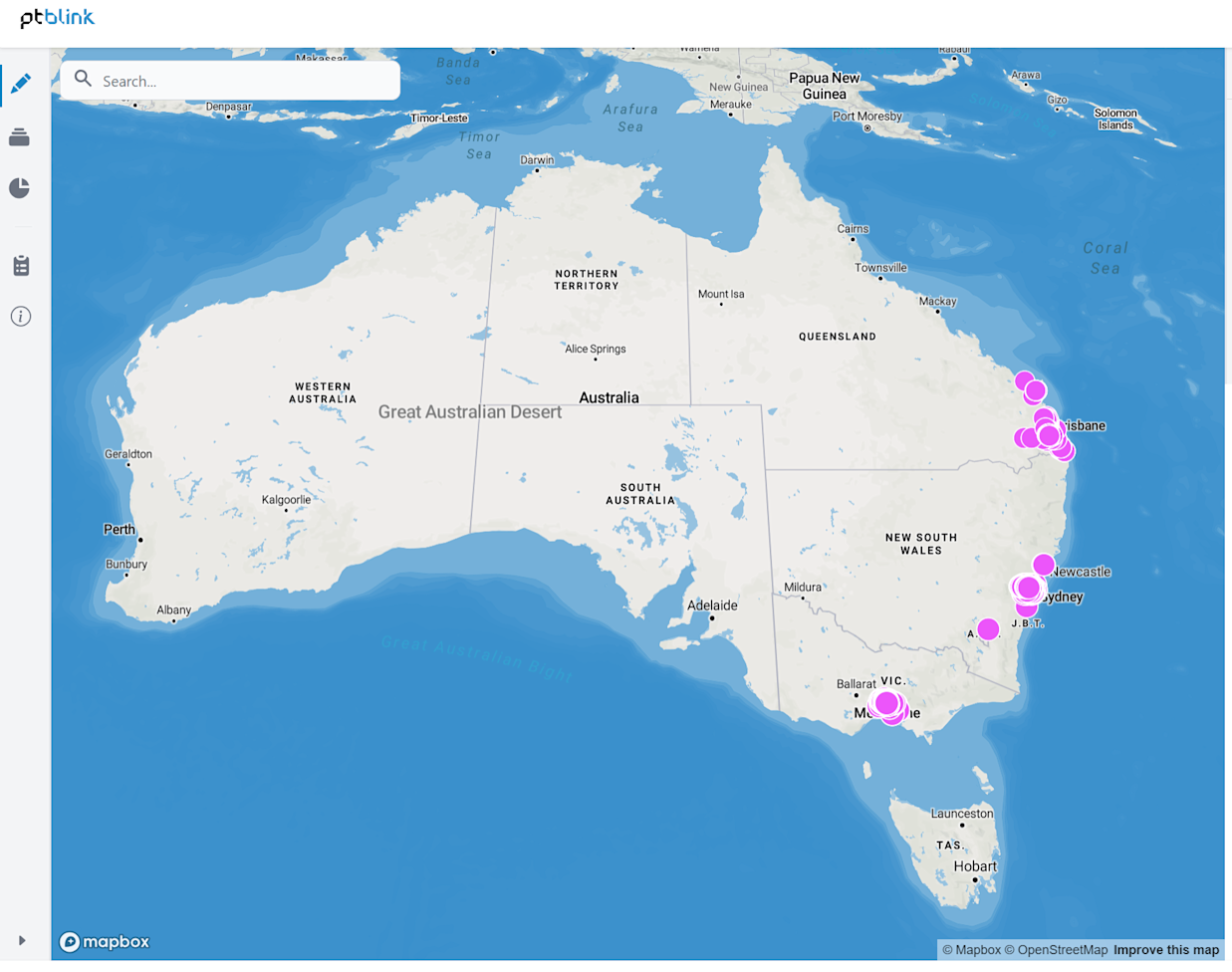

What's your footprint?

We've started a company called National Ducting Solutions and we’re all working under that banner towards offering a national solution. We've currently got the East Coast covered.

How does Blink DMI® heading to the Cloud help you?

It's a game changer because it’s a completely new business model. Moving from one-off products to a catalogue range offers benefits for everyone. Let’s say we standardise on seven fan coil assemblies; we can set up seven racks and start stocking them and inserting into jobs as required. This range approach leads to continuous product refinement in terms of quality and production-cost savings. Like a compressor manufacturer or a generator manufacturer, we can build for stock and pull through into projects. Having a pipeline gives us predictability. It's literally the kanban system in operation for the built environment.

What do you see as the biggest advantages in local manufacturing for construction?

There is a huge value proposition based on certainty and understanding of total costs and value. What's the cost of my money? If it takes longer to deliver, then that’s a missed external cost. Warehousing is a cost. Flexible design adds value. Certainty of delivery and quality take out risk and add value. If I said I can build you something and deliver it in 12 months, that's different to two or three years. What happens to the cost of raw materials in that time? What happens to the marketplace in that time? Also, the cost of rework in mechanical packages can be huge and is not well appreciated. We tend to win high-risk jobs because there is no margin for error, and we guarantee delivery. Peace of mind is worth paying for.

Many of your people have been with you 18-20 years. How do you describe your culture?

It's a family culture and we have three rules that we all live by:

Know and teach the rules of business so our people understand how they add value that the customers pay for.

Track and keep score using a dashboard and real-time measurement.

Have a stake in the outcome – if KI makes money, you make money.

We also have a culture of continuous improvement – we look for 1% improvements every day and no suggestion is too small. The team all appreciate that it's like compound interest, and a 1% improvement every day for 365 days makes you 37 times better at the end of the year. It's very powerful and everyone is engaged as they have a share in our profits and want to make a difference.

We offer a lot of support to make a family atmosphere and that makes a real difference to people’s lives because it’s genuine. We provide lunch every day and have a personal trainer and a gym facility with a fulltime massage therapist available so anyone with an injury or a sore muscle can get treated quickly. We also do financial education and health education workshops with our guys. We have a bank manager they can access to get a discount on their home loan.

Our employees are our partners, and we could not deliver what we do without them!

_______________________________________________

Are you a designer, manufacturer or integrator (builder)? Register your interest in becoming a Blink DMI® Partner today.