Structural components

With Blink DMI®, the structural components provide the geometric reference point for the entire structure while also enabling creative freedom to enable any design expression.

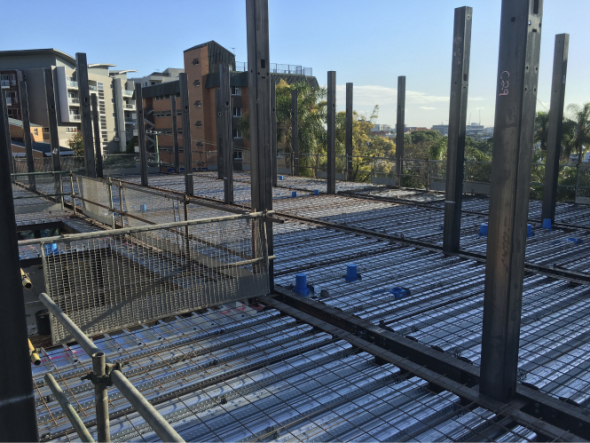

Using post-tensioned steel cables, the Blink Backbone® enables large, self-supporting spans and eliminates the need of traditional construction to rely on lift cores for stability. By removing the superstructure from the critical path, the entire build process is accelerated and requires other non-structural components to be manufactured with the same speed for just-in-time delivery and integration. This process is managed with precision and transparency by Blink DMI® Cube.

The Blink Backbone® comprises columns, trays and blades which are manufactured offsite and transported to the building site for integration. The Blink Backbone® fully integrates safety, reinforcement, building services and penetrations into the trays ensuring significantly faster and safer floor installation cycles. Once integrated, the columns and trays are filled with concrete. At this point, the structure behaves as if it were a traditional reinforced concrete structure, though with far greater dimensional accuracy, allowing the concurrent manufacture and integration of the non-structural components.

The Blink DMI® method is open to using other structural systems to flexibly cater to the required performance attributes of the design.

Seismic performance

The Blink Backbone® offers excellent earthquake response due to the greater ductility offered by post-tensioned steel. This technology allows structures to deflect significantly without failure. By way of comparison to concrete structures, the Blink Backbone® is often half the weight which halves the applied earthquake forces. A similar comparison with conventional steel structures gives 30% less earthquake forces. PT Blink’s post-tensioned steel technology is also well suited to foundation isolation systems or upper storey damping mechanisms.

Non-structural components

By designing all components for manufacturing and integration, the Blink DMI® process maximises speed and reduces costs. All components such as façades, stairs, bathroom pods, elevators, walls ceilings and windows are manufactured offsite and checked for fit by the Blink DMI® Cube and through physical testing.

In addition to ensuring millimetre-precision and fit with the structural backbone, the factory-based assembly is far safer than onsite construction. It also includes the pre-installation of services such as plumbing and electrical, which saves time and the need for trades onsite.

Through just-in-time delivery and on-site integration by accredited builders, the inefficiencies of a traditional construction project are significantly reduced or eliminated.