Accredited manufacturer partner network

PT Blink’s ecosystem of accredited manufacturing partners develop the Blink Backbone® and components that integrate seamlessly with them.

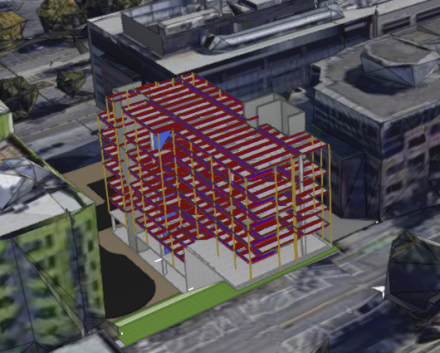

Advanced robotic technologies are used to manufacture the Blink Backbone® directly off the 3D model.

Point cloud technology is used to scan manufactured components and compare their geometric integrity against the design model.

Just in time production schedule

After the design and full digital clash detection have been completed, manufacturing of building components commences in parallel with the Blink Backbone®.

Manufacturers develop fully detailed 3D models of their components to integrate seamlessly with the Blink Backbone® and other manufactured components.

Components are manufactured in line with the integration schedule to accelerate the project program.

Centralised control via the digital twin

The procurement of manufactured components is verified and tracked electronically against smart contracts derived directly from the digital twin.

This technology facilitates the transfer of title and initiates payment of components down to the unit level.

Product documentation including testing, certification, warranties and source are captured in the digital twin for full traceability and future reference