Blink DMI® Cube

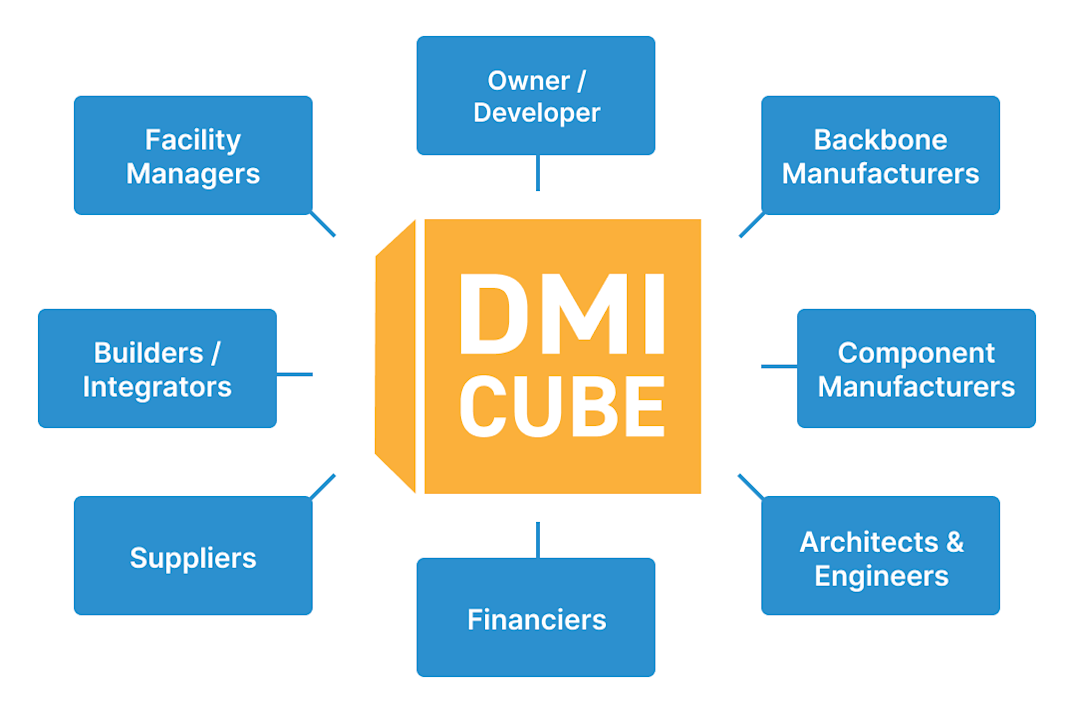

Blink DMI® Cube comprises a set of services and proprietary algorithms that ensure complete geometric accuracy throughout the Design – Manufacture - Integrate process. Manufacturers make their digitised components available to the ecosystem members by ‘publishing’ them to the Blink DMI® Cube as a catalogue of components.

Designers can select from a wide and constantly growing range of customisable components provided by accredited manufacturers. These components include backbones and non-structural elements.

Designers first overlay the backbone structure on the architectural plans. Using the Auto Blink concept-design process, PDF floor plans are simply loaded into the platform and with slab edges and a structural grid used as reference points a 3D structural design is ready in seconds for analysis and detailed design. With the structure ready, non-structural components are then dragged and dropped into the structural backbone and dimensionally adjusted.

AI technology enhances the experience by completing repeatable elements. Components are ‘snapped’ into place with precision to meet the dimensions, freeing the designer to focus on creativity rather than time consuming details.

Once design is complete, a digital twin instructs the manufacture and integration phases, tracking all information down to a component level, including chain of custody, warranty and compliance.